Progressive Cavity Pumps

Progressive Cavity Pumps Specification

- Usage

- Industrial

- Material

- Cast Iron

- Power

- Electric

- Product Type

- Progressive Cavity Pumps

- Color

- Light Green

Progressive Cavity Pumps Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 5 Pieces Per Day

- Delivery Time

- 7 Days

- Main Export Market(s)

- Western Europe, Australia, North America, Eastern Europe, Middle East, Central America, South America, Asia, Africa

- Main Domestic Market

- All India

About Progressive Cavity Pumps

We are Leading Manufacturer and Exporter of Progressive Cavity Pumps in Tiruchengode, Tamilnadu, South India.

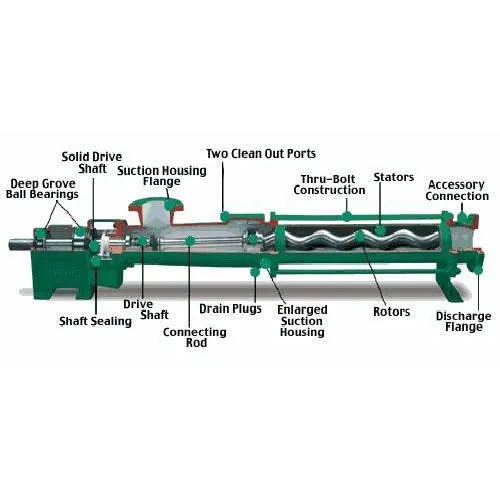

Profik progressing cavity pumps is a positive displacement rotary pump. The actual pumping elements of the pump are rotor and stator. The single helical rotor rolls eccentrically in a double threaded helix stator of twice the pitch length. A series of sealed cavities 180 Degree apart are created that appear to progress from suction to discharge during one rotation of rotor. The opposing cavities fill and empty simultaneously resulting in a pulsationless flow. The fluid travels axially with relatively low velocity and minimal agitation. The stator is made of a resilient elastomeric material and bonded to the stator tube. The important feature of the pumping principle is the ability to handle slurries and solid particles. The elastomer stator also permits passage of solid particles due to elastomeric deformation. The compression fit of the rotor and stator enables the Profik progressing cavity pumps to handle gaseous and low viscosity liquids. The pressure capabilities of the pump are a function of the number of cavities. Profik progressing cavity pumps are available in a wide variety of materials - cast iron or stainless steel wetted parts and 10 standard elastomer materials. Profik versatile progressing cavity pumps are rugged, compact and highly efficient. Fluids, which are delicate, shear sensitive or abrasive, low or high viscosity, with fibres, with high air content, or large solids, can be conveniently handled by Profik progressing cavity pumps.

Features:

Long Lige

On Time Delivery

Quality Service

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Progressive Cavity Pumps Category

Hopper Design Mango Pulp Progressive Cavity Pump

Minimum Order Quantity : 10 Pieces

Power : Electric

Usage : Water

Product Type : Progressive Cavity Pump

Color : Blue

Material : Stainless Steel

Coimbatore Progressive Cavity Pumps

Minimum Order Quantity : 1 Piece

Power : Electric Volt (v)

Usage : Food

Product Type : Progressive Cavity Pumps

Material : Stainless Steel

Close Coupled Progressive Cavity Pump

Minimum Order Quantity : 1 Piece

Power : Electric

Usage : Industrial

Product Type : Close Coupled Progressive Cavity Pump

Color : Blue

Material : Stainless Steel

Affordble Price Progressive Cavity Pumps

Minimum Order Quantity : 1 Number

Power : Electric

Usage : Industrial

Product Type : Progressive Cavity Pumps

Color : Blue

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free